plug flow reactor example

This elementary reversible reaction is to be carried out adiabatically in the liquid phase under high pressure using a liquid catalyst which gives a specific reaction rate of 311 h -1 at 360 K. F Y 0-2 H Y -2 F.

Sizing A Plug Flow Reactor Pfr Youtube

Plug flow reactors PFR are a very specific type of reactor different from agitated vessels for example.

. IIIC3ai Plug flow reactors. Tz T o isothermal reactor. The reaction occurs along the flow path.

A window should open that looks like this. Continuously Stirred Tank Reactor CSTR Arranged as one long reactor or many short reactors in a tube bank. DC d r C Ideal batch.

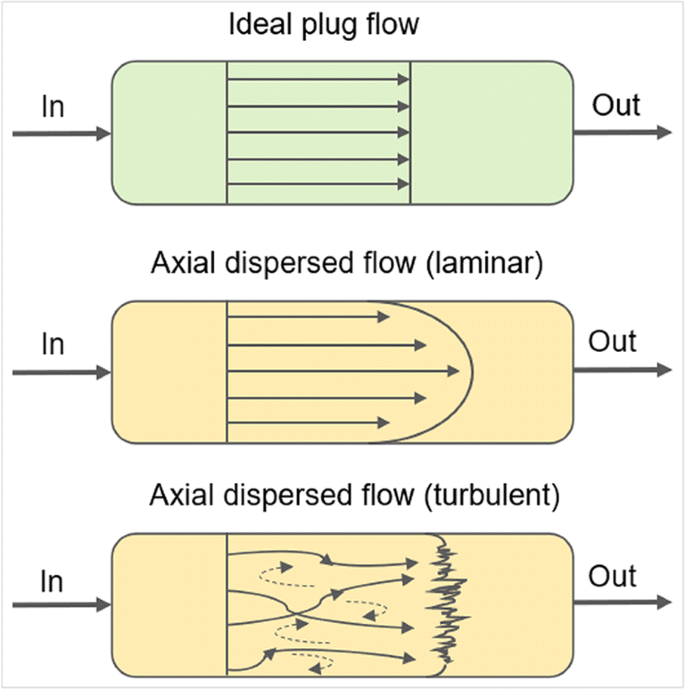

The degree of mixing and residence time in reactors affect the degree of completion of reactions within the reactor. Most reactors used in industry approximate the ideal batch reactor PFR or CSTR. Other simplifications used are perfect radial mixing and a homogeneous.

Lakes segments of a river and settling tanks in treatment plants are examples of reactors. Example 11-3 Adiabatic Liquid-Phase Isomerization of Normal Butane. Some examples of reactors include lakes rivers and sedimentation tanks.

Normal butane C 4 H 10 is to be isomerized to isobutane in a plug-flow reactor. Valve objects are often used between an upstream reactor and a. Integrate 8 or 13 find ξz.

Isothermal plug flow reactor A C B z0 z3 The components A and C react to form component B. Sum P Y -1 Ftot F. The plug flow model has many practical applications.

One type of reactor designed to model these conditions is the Drip Flow Reactor DFR. For example the reactor may consist of a tube placed in a bath a tube in a jacket or a. No radial variation in reaction rate concentration.

The analytical form of the objective function is encoded in the PFR model. Integrate 8 or 13 and find extent along the reactor. Plug Flow Reactor Example Add Comps.

This example considers the thermal cracking of acetone which is a key step in the production of acetic anhydride. The temperature in the reactor is prescribed a. There is no mixing in the direction of flow.

Kayode Coker in Ludwigs Applied Process Design for Chemical and Petrochemical Plants Fourth Edition 2015. AspenTech channel has brought another exciting video for its valuable viewers. Page of the Simulation Basis Manager.

Plug Flow Reactor Example This example will take you through the entire process of setting up multiple reactions and creating a plug flow reactor in HYSYS as shown in the picture above. For the case of the plug flow reactor the advection-dispersion equation in 17 reduces to. Now that you are done creating your reactions you must add them to.

One example is in the design of chemical reactors. The plug flow tubular reactor is a heat exchanger in which the reaction occurs in the tubes. EXAMPLE Gas Phase Elementary Reaction Additional Information.

Concentration changes with length down the reactor. Compare ideal batch and ideal PFR mass balances. This sort of reactor geometry is quite common in nature in any habitat where water flows over a surface either continuously or intermittently.

The PFR model is developed for the acid-catalyzed dehydration of fructose to HMF using HCl as the catalyst. The gas phase reaction takes place under nonisothermal conditions in a plug-flow reactor. This implies for example that if a 20-m reactor of fixed diameter is required to achieve a given conversion the same conversion and capacity can be achieved by running ten 2-m reactors in series or ten 2-m.

In fact real reactors can be modeled as networks or combinations of multiple plug-flow and stirred-tank reactors Towler and Sinnott 2013. This results in differential equations that need to be integrated to find the reactor conversion and outlet temperatures. Their construction is varied.

Return-r 0 H_A-r 1 H_B r 2 H_C define the plug flow reactor model def plug_flow_reactor_gas z Y dpdz model_param reaction_model. 9 or 14 find the heat additionremoval requirement along the reactor and the overall heat duty for the reactor. EXAMPLE 185 PLUG FLOW REACTOR SIZE FROM RATE ---------- CONCENTRATION DATA.

Sequencing batch reactors have a sequence of states including fill react and empty. Instead of having the fluids in relatively large tank the fluid is pushed in a reactor having a cylindrical shape which can be as simple as a pipeThis page focusing in applying the general mass balance equations to PFR reactors. Press Add This Group of Components and then close the window.

In this example we will demonstrate how Bayesian Optimization can locate the optimal conditions for a plug flow reactor PFR and produce the maximum yield. As the cracking chemistry is endothermic control over the temperature in the reactor is essential in order to achieve reasonable conversion. The mole balance for each component is given by the following differential equations A22 A dC uk dz C1 B22 A dC u dz kC2 C0 dC u dz.

A shower curtain the walls of a bathtub or a canyon wall seep all exhibit the properties of an open plug flow reactor. Continuous Isothermal Plug Flow Tubular Reactor. We can imagine this as little discs or plugs of fluid moving through the reactor in a single file line like miniature batch reactors moving through the reactor.

A plug flow reactor PFR is a type of chemical reactor where the influent is pumped into the pipe. Most but not all reactors experience continuous flow in and out. DC dt r C Position in a PFR is equivalent to time in a batch reactor x C.

Append dP return dY define initial. In an ideal PFR is the absolute residence time for mass flowing through the reactor not the average residence time as in a CSTR. Sum x f Ftot for f in F T H Cp r reaction_model x model_param T P dH calc_DeltaH r dP -dpdz dY r dY.

Essentially no back mixing is assumed with plugs of fluid passing through the reactor. Examples of real reactors that approximate the flow pattern of ideal reactors are shown in Figure 10. Pg414 Example 5 Percent Approach to Equilibrium For a reversible reactionwith rate equationr LA 1 AVl6 the size functionkVV of a plug flow reactorwill be found in terms of percent approach to equilibrium.

Plug flow reactors are unique in the sense that operation in parallel or series give the same conversion if the space time is held constant. In order to be an ideal plug flow reactor two assumptions must be met. Plug Flow Reactors PFRs Type of Reactor.

The pressure difference between upstream 1 and downstream 2 reservoir is defined as P_1 - P_2It is never possible for the flow to reverse and go from the downstream to the upstream reactorreservoir through a line containing a Valve object which means that the flow rate is set to zero if P_1 P_2. Lecture 64 is focused on the simulation of the plug flow rea. The same example problem has been worked in Aspen and Matlab.

Add Set to Fluid Package. A plug flow reactor is operated as shown in Figure 1 below.

1 4 Continuous Flow Reactors Elements Of Chemical Reaction Engineering Mole Balances Informit

Matlab In Chemical Engineering At Cmu

1 4 Continuous Flow Reactors Mole Balances In Chemical Reaction Engineering Informit

Plug Flow Reactor Overview Youtube

Variable Density Reaction In A Pfr Youtube

Plug Flow Reactor Vapourtec Ltd

Mole Balance On A Plug Flow Reactor Youtube

Completely Mixed Flow Reactor Cmfr And Plug Flow Reactor Pfr Cmfr V S Pfr Youtube

Plug Flow Reactor An Overview Sciencedirect Topics

Visual Encyclopedia Of Chemical Engineering

Deviation From An Ideal Flow Pattern Part 1 Petroleum Refining

Reactor Design And Selection For Effective Continuous Manufacturing Of Pharmaceuticals Springerlink

Transient Dynamics In A Plug Flow Reactor Pfr Download Scientific Diagram

Experimental Setup Of The Plug Flow Reactor With Tof Ms Download Scientific Diagram